blow molding machine parts name

The tube of the blow molding machine also commonly known as the Parison later hangs on the mandrel and the mold halves close on it. Trained and experienced employees with access to original design information of your machine.

Shop Our Huge In-Stock Selection Or Call For Custom Orders.

. Blow molding machines are used within the plastics manufacturing industry to make bottles of all types. This is done by pressing the plastic around or over a. Ad Browse discover thousands of brands.

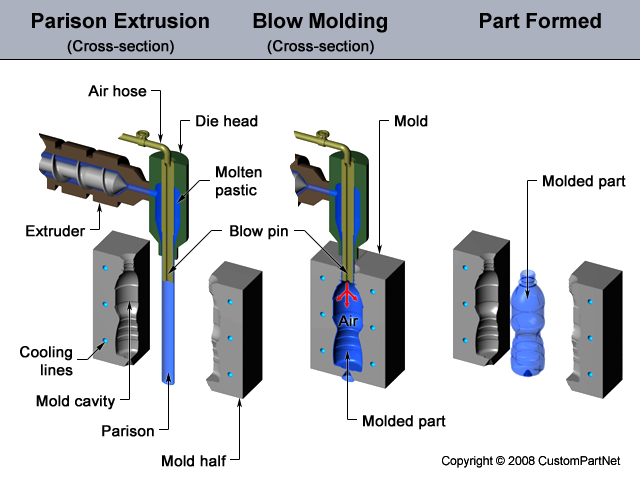

It turns the solid melt flow into a hollow tube. Injection blow molding - The molten plastic is injection molded around a core. Like other molding processes blow molding machines generate their finished product through use of heated plastic and a mold cavity in which the liquid is shaped and cooled into its final form under pressure.

The female mold halves contain the shape of the product to be produced. Blow moulding machine parts name on sale manufacturers find details about blow moulding machine parts name manufacturers supplier and wholesaler - HEBEI SANQING MACHINERY. A list of these blow molding machine parts name articles makes it easy for you to quickly access relevant information.

We have prepared the following professional blow molding machine parts name hoping to help solve your questions and better understand the. Sidel lamp 00000159384 00000159385 0. HDPE is the worlds 1 plastic and the most commonly blow molded plastic material.

Blow moulding machine parts name on sale manufacturers find details about blow moulding machine parts name manufacturers supplier and wholesaler - HEBEI SANQING MACHINERY. 19850 State Line Road South Bend IN 46637 Phone. In-Stock Ready To Ship.

528 Jinyuan Road Yinzhou. Service and Parts available 247 for Blow Molding Machines. Producing the highest quality containers for a broad range of applications container sizes and production requirements Wilmington Machinerys all-electric.

Low density Polyethylene LDPE High Density Polyethylene HDPE Polypropylene PP Polycarbonate PC Polystyrene PS Co-polyester Polyethylene Terephthalate PET Polyvinyl Chloride PVC Nylon Acrylonitrile Butadiene Styrene ABS are the main resins utilized with blow molding. Free Shipping On Orders 200. Wilmington Machinery is the recognized leader in high-speed monolayer and multilayer rotary extrusion blow molding machines and systems.

Extrusion blow molding is one of the simplest types of blow molding where a hollow tube parison is formed. Reservoirs buoys and other items are commonly made with blow molding. Blow Molding Machines Guide.

Ad Wholesale Plastic Glass Containers Bottles Jars Closures. If you have a new mold set we are able to provide you the new auxiliary tooling to go along with it. Read customer reviews find best sellers.

Spare parts for blow molding machine s. Angular-contact thrust ball bearing 0. If you have things like deflashing or facing and reaming that are needed we have the resources and expert.

The parison is extruded vertically between the two open mold halves so they can close on the parison and blow pin. BLOW MOLDING High-Speed Extrusion Blow Molding Systems. The blow molding process.

The extrusion head is the heart of any blow molding machine. This is the most common type of blow molding and is used to manufacture large quantities of relatively simple parts. Right gripper 0905087425 090508744.

Spare parts for blow molding machine s. The process consists of extruding or dropping a parison on which female mold halves are closed. Examples of parts produced on this machinery include drums trash cans automotive panels playground equipment and large containers such as Jerry Cans for liquid storage.

A blow pin inserts into the middle of the parison and blows the plastic into the shape of the surrounding mold. Pressurized air flows through the blow pin to inflate the parison. Stretch blow molding is a variation of injection blow molding which is also primarily used to make clear PET bottles.

Spare parts for blow molding machine b. Monroe Mold has the expertise to design build or repair blow pin and take-out tooling for your blow mold machines. Blow molding is the forming of a hollow object by inflating or blowing a thermoplastic molten tube called a parison in the shape of a mold cavity.

It forms one or more parisons from the melted plastic which comes out of the extruder s. Accumulator Head Machinery is used for the extrusion blow molding of large industrial hollow parts.

Car Bumper Making Machine Plastic Parts Injection Molding Machine In 2021 Plastic Moulding Plastic Injection Moulding Machine Plastic Injection Molding

Extrusion Blow Molding An Overview Sciencedirect Topics

Ningbo Hairun Yiye Plastic Machinery Co Ltd Plastic Injection Plastic Injection Molding Injection Moulding

Pin On Ibm Injection Blow Molding

Plastic Molding Machine Injection Blow Molding Machine Manufacturers

Husky Names Mark Segal Chief Financial Officer India International Plastics News India Plastics News Portal Husky Husky Names Chief Financial Officer

Injection Molded Liquidmetal Targets Mim Machined Parts Plastics News Global Plasti Injection Moulding Plastic Injection Moulding Machine Plastic Industry

Pet Bottle Blow Molding Machine Ibottling

Product Design Extrusion Blow Molding Machine Parts And Functions

Blow Molding What Is It How Does It Work Materials

Blow Molding An Overview Sciencedirect Topics

Blow Moulding Machines Windsor Machines Limited Pdf Catalogs Technical Documentation Brochure

The Blow Molding Process The Blow Moulding Process In By Peter Denker Medium

Blow Molding An Overview Sciencedirect Topics

Mattel Mabamex Injection Molding And Blow Molding Auction Blow Molding Plastic Moulding Auction

Blowmoldmachine Names Are Generally Confusing To Remember These Terms Are Used On A Daily Basis In Blow Molding Machine Business So Blow Molding Blow Molding